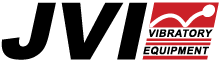

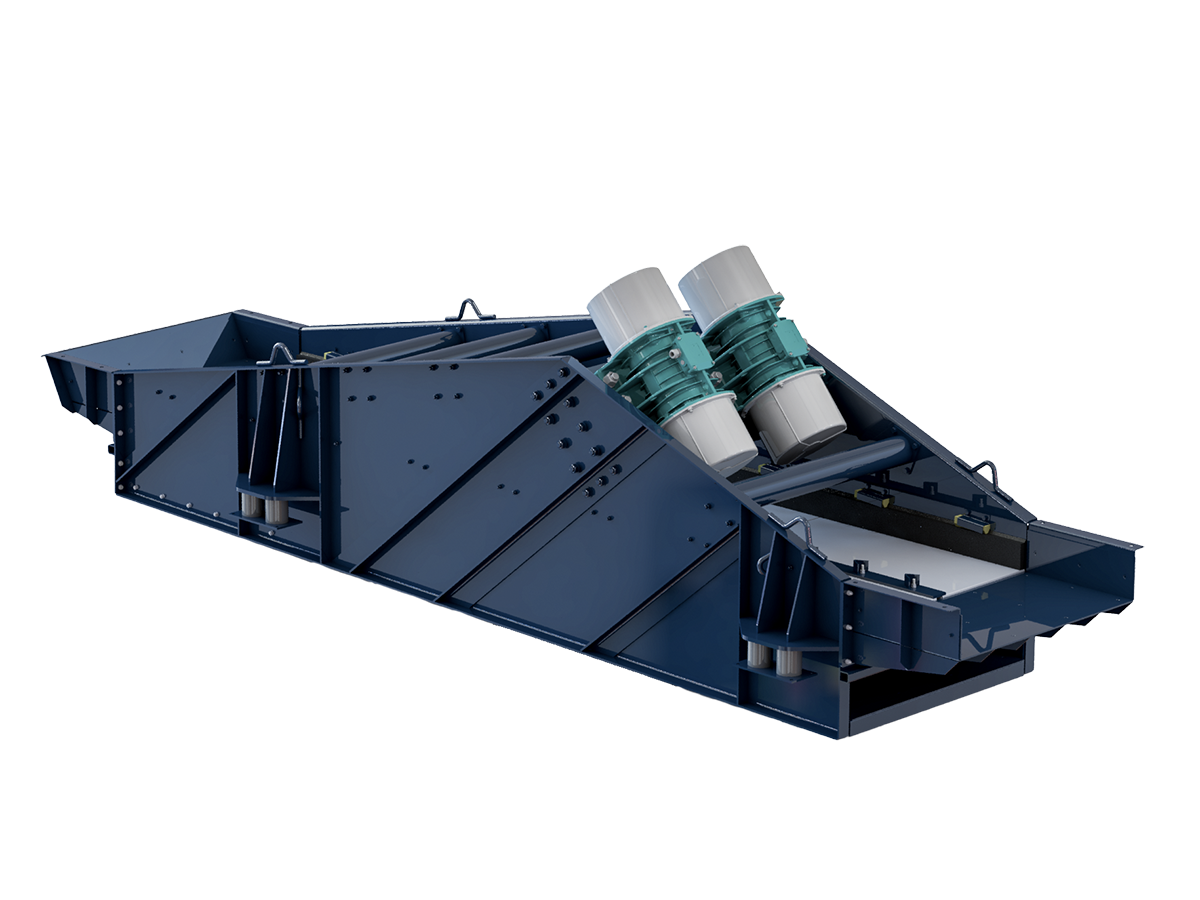

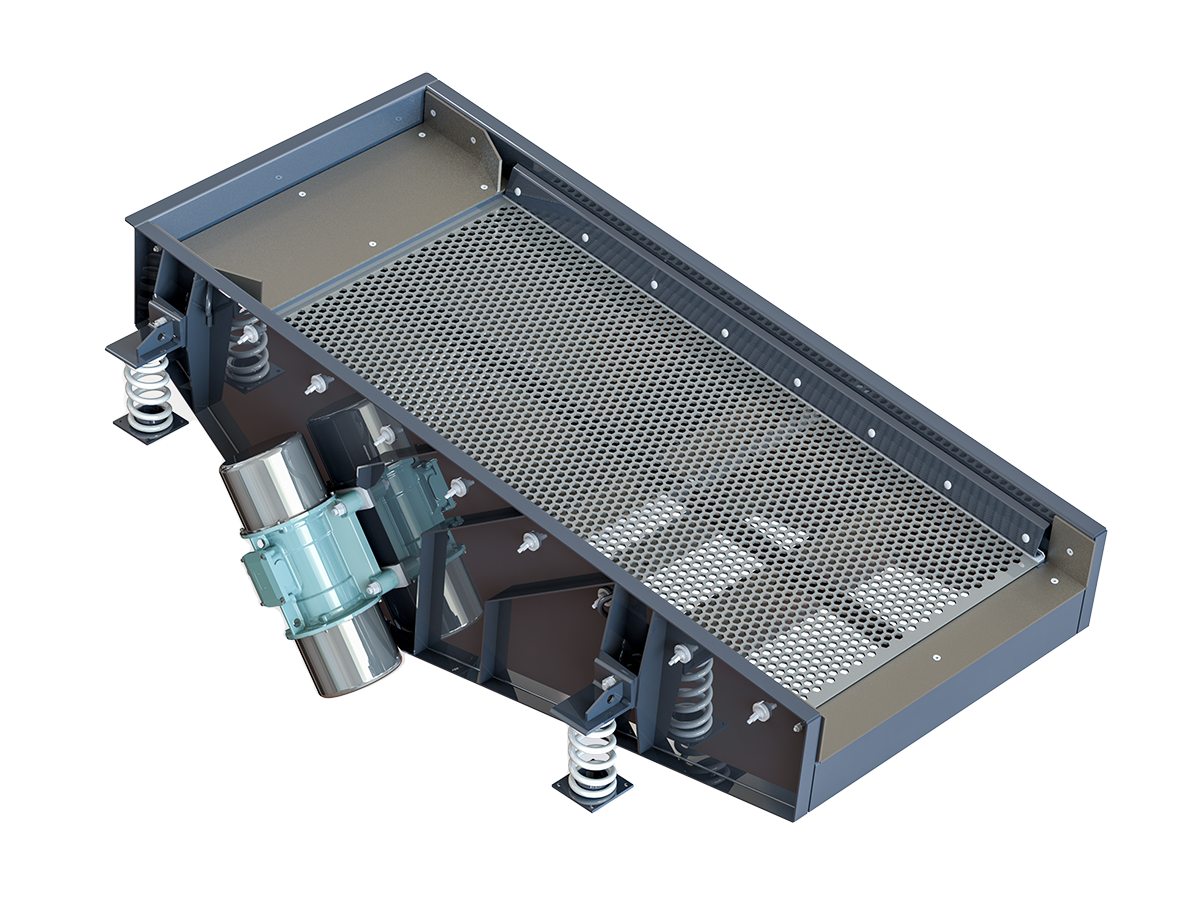

Vibratory screens separate bulk materials for processing across a wide range of applications and industries.

Screening improves efficiency and protects downstream equipment. JVI custom designs vibratory screens for processing heavy quarry products, metal alloys, plastics, glass, grain, food & beverage, and more.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you: