Vibratory dosing feeders ensure precise feed rates for accurate bulk material processing.

Electromagnetic feeders combine superior feed rate control with application flexibility.

Electromagnetic vibratory dosing feeders are designed for accurate and reliable control in mixing, dosing and batching applications. Zero to 100% feed rate adjustability and instant start/stop operation make the dosing drive ideal for either continuous feeding or producing the accurate measurement required.

The feed rate adjustability and stop/start capability of these magnetically-driven feeders deliver accurate, repeatable performance making them ideal for loss-in-weight and gain-in-weight metering applications.

JVI electromagnetic feeders are virtually maintenance free. They are factory-tuned, so they do not require field tuning, greasing or lubrication.

JVI vibratory dosing feeders deliver accurate and reliable feeding of bulk material in mixing and dosing applications.

Strong construction for durability.

JVI vibratory dosing feeders are built for durability and used across many industries, including food & beverage, plastics, ceramics, chemicals, cosmetics, packaging, feed & grain, and more. Precise dosing feeders are an indispensable component in successful packaged goods production today.

JVI delivers electromagnetic dosing feeders to customers across North America and around the world. Driven by an electromagnetic drive, it generates a high-frequency, low-stroke pulse that gently moves material through the feeder in a micro-throw motion.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Flexible control.

JVI electromagnetic dosing feeder feed rates are adjustable from zero to 100%. Each electromagnetic feeder is controlled by a thyristor controller that enables local manual operation.

A programmable logic controller (PLC) interface enables remote control for loss-in-weight (L-I-W) or gain-in-weight (G-I-W) applications.

Custom control packages are available for unique process requirements.

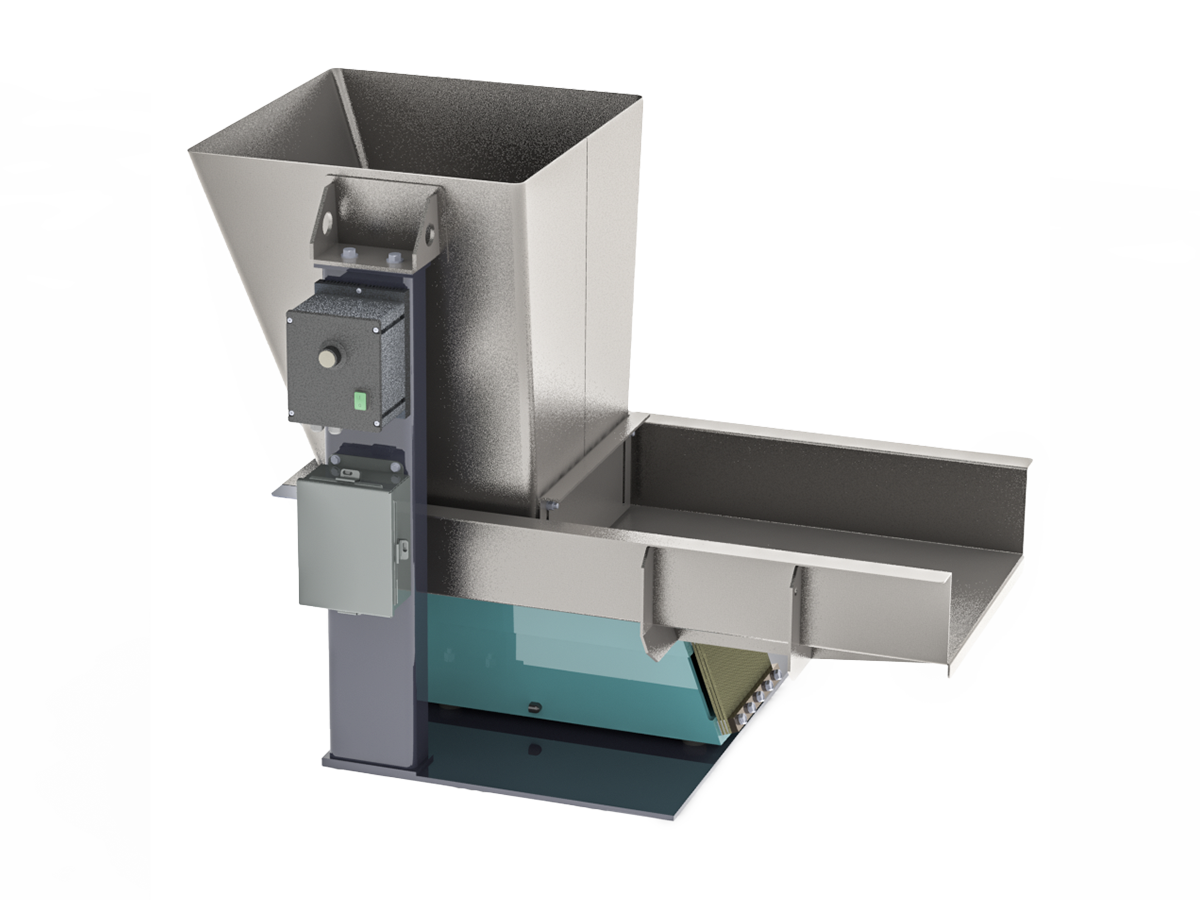

Custom JVI dosing feeders with custom stand and integrated hopper for bed depth adjustment, see through cover, and individual thyristor controllers.

Custom engineered for your application.

From the type and amount of material to environmental conditions, every application presents its own unique challenges. The JVI engineering team works directly with our customers to provide vibratory dosing feeders that integrate into your processes and meet the exact material and environmental conditions you face.

Dosing feeder with polycarbonate cover.

New feeders retrofit to your process.

We design new feeder systems and also design feeders to be retrofitted into your current process. This means you get all the benefits of a new higher performing feeder without the costs associated with having to redesign your current process.

Integrated hoppers for the plastics industry.

Integrated hoppers.

Integrated hoppers with base support stands are available with all electromagnetic dosing feeders. The hopper is designed for exact volumetric storage capacity and deliver proper material flow into the dosing feeder to ensure optimum performance. All hoppers are available with and without lids, liners and/or vibrator flow aids.

Stainless steel, corrosion-resistant drive.

Heavy-duty applications, too.

JVI dosing feeders are capable of feeding grams per minute up to tons per hour. While vibratory dosing feeders are primarily found in light-duty applications, they do heavy-duty work also, such as feed & grain processing where volumes are measured in tons not grams.

The JVI Material Testing Lab provides testing of the bulk material properties in a simulated application.

With this data, JVI engineers confirm the feeding and conveying characteristics of the bulk material and optimize design.

Gentle Handling and Food Grade Finishes

The micro-throw vibration in electromagnetic vibratory dosing feeders is ideal for moving friable or fragile materials into the next phase of processing. Electromagnetic vibratory dosing feeders are available with food-grade finishes for food, beverage, ceramics, chemicals, and cosmetics.

Pans, Tubes, and Covers

All electromagnetic dosing feeders are available in standard pan configurations with optional bolted and removable covers to mitigate dusting. Additionally, they are available in round, square or rectangular tube configurations.

Electromagnetic Drives Rated to Work in Any Application

JVI feeders are powered by electromagnetic drives featuring:

- Many different models available including 25, 30, 50 & 60 Hz versions

- Suitable for wash-down

- Explosion-proof CSA certifications available on certain models