Vibratory tube feeders fully enclosed designed is ideal for dust control and differential pressure applications.

Multiple inlets designs allow for mixing while feeding.

JVI vibratory tube feeders move material horizontally at a controlled feed rate through a fully enclosed space.

Tube feeders are used across a wide variety of industries and every JVI vibratory tube feeder is designed specifically for the application and its work envelope constraints.

JVI vibratory tube feeders convey material horizontally at controlled feed rates.

Heavy-duty construction.

JVI vibratory tube feeders are used widely across many industries, including mining and aggregates, steel, recycling, plastics, chemicals, food & beverage and more.

JVI delivers vibratory tube feeders to customers across North America and around the world. Tube feeders have become an essential component in today’s production systems.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Enclosed Feeders for light and medium duty applications.

Regulating flow. Controlling Dust.

Regulating Bulk Material Flow

JVI vibratory tube feeders with square or tube geometry can be tailored to work in light- and medium-duty applications. They are ideal for discharging bulk materials from hoppers, feeding roller mills, multiple batch conveying.

Handling Friable Bulk Materials

JVI vibratory tube feeders ensure that bulk material is handled gently to prevent damage. They are an alternative to screw conveyors as an ideal solution for handling fragile or friable bulk material.

Adjusting for Differential Pressure

JVI vibratory tube feeders are often used to regulate flow into vertical mills. Feed rate into the mill is modulated based on the mill’s differential pressure to optimize crushing performance. This reduces unnecessary wear and maintenance.

Effective Dust Management

The fully enclosed tube feeder design can be enhanced to reduce dust emissions. An inlet and outlet socket with dust-tight collar is an ideal option for dust management.

Accurate Mixing

JVI tube feeders utilize multiple inlets with controlled feed rate to accurately mix materials while feeding to downstream equipment.

Tube feeder designed for plastics processing.

Tube feeder controlling dust in cement plant.

Tube feeder designed for steel plant.

Application specific. Engineered to order.

From the type and amount of material to environmental conditions, every application presents its own unique challenges. The JVI engineering team works directly with our customers to provide vibratory tube feeders that integrate into your processes and meet the exact material and environmental conditions you face.

Integrated tube feeder in the steel industry.

New tube feeders built to fit your existing process.

The JVI engineering team applies advanced vibratory technology to design tube feeders that can be easily integrated into your existing production lines. JVI feeders are designed to combine with other equipment, such as conveyors, screens, or crushers to create a seamless bulk material handling process.

Our goal is to provide you with a new, high-performing tube feeder system without the time and cost of changing your existing process.

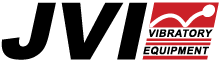

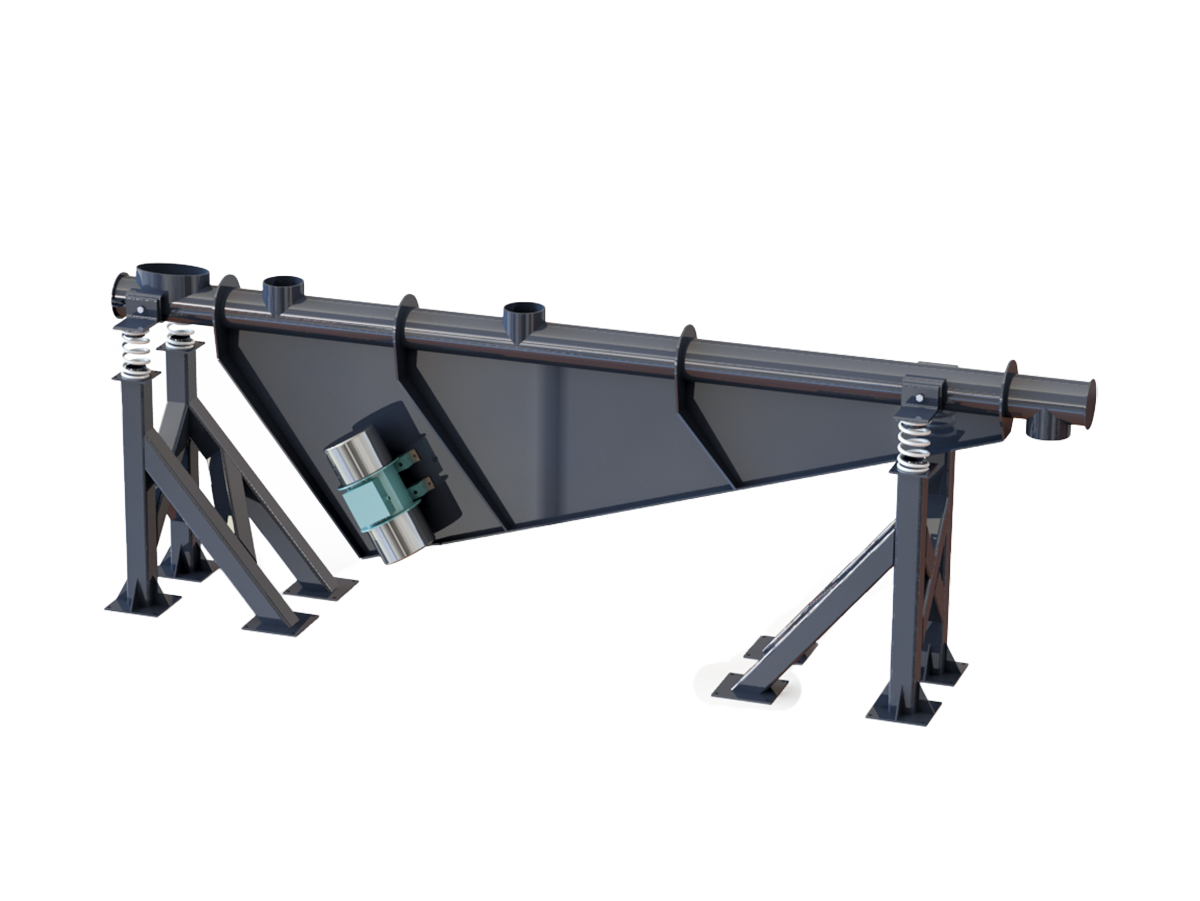

Static downcomer package ensures proper material flow.

Static downcomer packages are used with electromechanical and electromagnetic tube feeders to act as a transition mechanism controlling the flow of material into the feeder. They are mounted to the outlet of hoppers, bins, silos, or other storage vessels and extend into the feeder’s inlet. The feeder is able to vibrate freely while the static downcomer controls the material height (bed depth) within the feeder ensuring proper material flow. Static downcomers are designed to work in combination with dust tight collar and jacket (flex boot) to ensure effective dust management. In addition to tube feeders, static downcomers can be used with covered pan feeders.

Tube feeder with static downcomer.

The JVI Material Testing Lab provides testing of the bulk material properties in a simulated application.

With this data, JVI engineers confirm the feeding and conveying characteristics of the bulk material and optimize design.

Bi-directional tube feeders convey material into multiple discharge points.

JVI vibratory tube feeders can be designed to convey material in two different directions. This unique design feature enables the operator to electronically switch direction. Bi-directional feeders are typically used to discharge one hopper and convey the material to one of two different discharge points.

Bi-Direction Tube Feeder in Action

This video shows the electromagnetic bi-directional tube feeder conveying bulk material through its dust-tight tubular enclosure. This bi-directional feeder is able to change conveying direction almost instantly, allowing material to be discharged from one of two discharges located at opposite ends of the feeder.

Simple Design, Less Maintenance Required

Simple design with few moving parts reduces mechanical failures for lower maintenance costs and less downtime.

Easier Inspection and Cleanout

Dust tight inspection covers, quick disconnect end covers and hatches combined with no internal moving parts allow for easy clean out and inspection of the feeder.

Food Grade to Explosion Proof

JVI will customize the vibratory tube feeder to meet your exact application requirements, such as food grade stainless steel, replaceable tube or abrasion resistance liner for abrasive material, and handling explosive materials.

Two drive options for custom implementation.

Mechanically-Driven Tube Feeder

Single Mass Design Provides Superior Performance for Continuous Feeding

The electromechanical tube feeder controls material flow rate from storage to downstream equipment. The single mass design provides a reliable and economical solution for continuous feed applications.

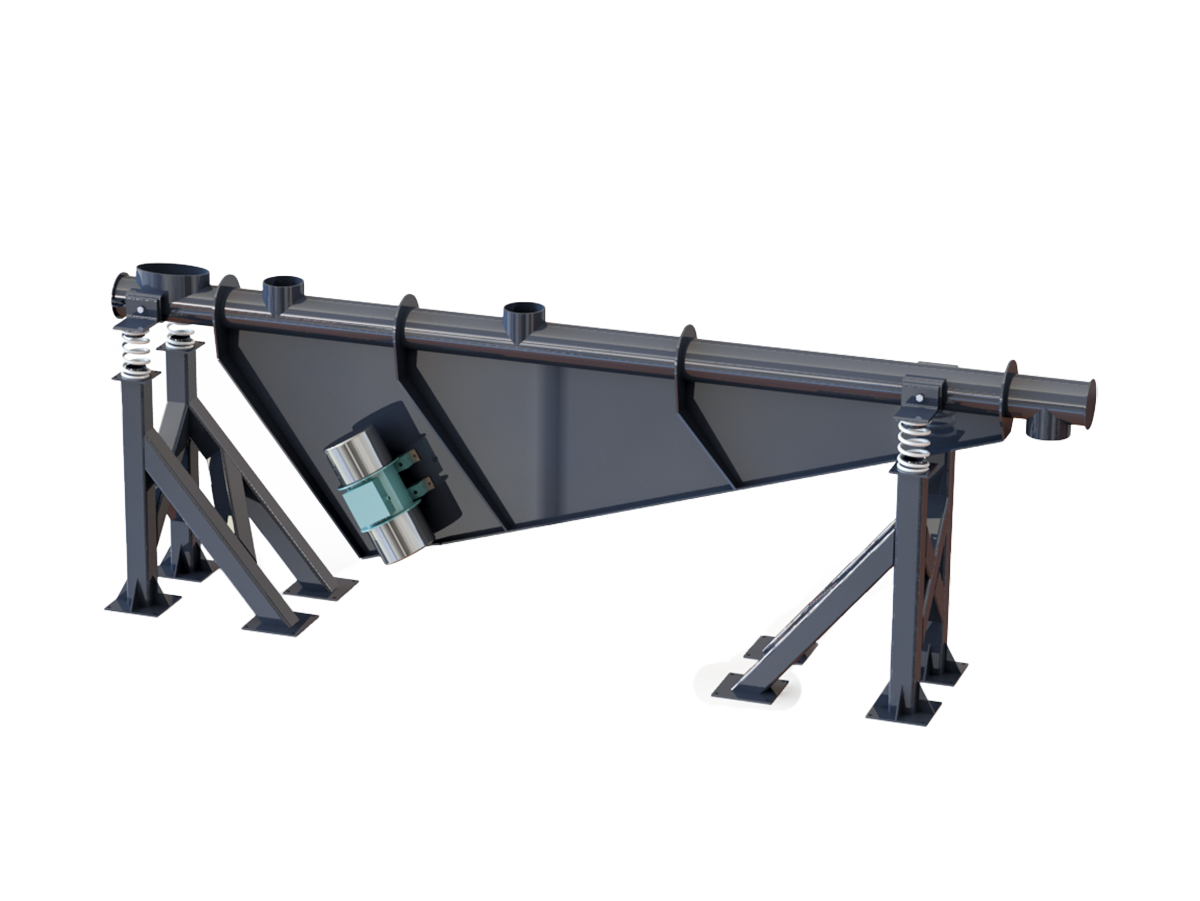

Magnetically-Driven Tube Feeder

Electromagnetic Drive Provides Superior Feed Rate Control

The electromagnetic tube feeder has instant start stop and zero to 100% feed rate control that enables precision in material feed rates in batching or mixing applications. Customizable to the application with top or bottom mounted drives.

Every JVI vibratory tube feeder – electromechanical or electromagnetic – is designed specifically for the application and work envelope constraints. For help deciding which option is right for your application, contact a JVI engineering expert. For immediate attention, please call +1 (832) 467-3720.

Comparison of Features

Mechanically-Driven Tube Feeder

Single Mass Unbalanced Motors

With single mass construction, the feeder is driven by two electromechanical unbalanced motors mounted directly to the feeder body, also known as the saddle.

Single mass technology eliminates the need for exciter springs or natural frequency tuning to generate the required peak to peak movement that is typical of two mass feeders that are found in the North American market.

Simple Design = Higher Run Time

Simple design with fewer moving parts keeps electromechanical tube feeders working, even in the harshest industrial environments. Exciter springs, v-belt drives, and sheaves required in two-mass vibratory feeders are eliminated, reducing maintenance and part replacement problems.

In this simple design, natural frequency tuning is not necessary. Mechanical failures with tuning spring failures and sensitivities due to natural frequency tuning are eliminated.

Motors Rated to Work in Your Application

JVI electromechanical unbalanced motors are selected per application requirements. These motors are:

- Available in 94 different models, including 3600, 1800, 1200 and 900 RPM versions

- Rated for continuous duty at 100% force output and suitable for wash-down

- Explosion-proof CSA certified Class II, Division I, Groups E,F,G for dust environments

- Class I Division II certified motors for gas available upon request

Enhanced Feed Rate Adjustability

When operated with a standard variable frequency drive (VFD), the feed rate can be continuously adjusted in real time to meet the changing dynamics of the industrial process.

The production process is automated and optimized when the sensor on the production line communicates with the VFD to adjust the feed rate as necessary.

Magnetically-Driven Tube Feeder

Electromagnetic drives for precise feed rate control

Electromagnetic tube feeders have instant on/off and zero to 100% feed rate control that high precision control of material feed rates.

Each feeder is tuned at the factory and works in conjunction with a thyristor controller.

The controller adjusts the amplitude or micro-throw of the material being conveyed in a linear manner, delivering precise feed rate adjustability that is best-in-class.

No Lubrication Required

JVI electromagnetic feeders feature quiet operation and minimal maintenance. They are tuned at the factory and do not require field tuning, greasing or lubrication making them virtually maintenance free.

Light-Duty to Medium Duty Bulk Material Feeding

Built for a wide array of applications, electromagnetic tube feeders are capable of feeding grams per minute to 750 tons/hour of selected materials.

JVI feeders are powered by electromagnetic drives designed exclusively for our vibratory equipment and selected per application requirements. These drives are:

- Available in many different models available including 25, 30, 33, 40, 50 and 60 Hz versions

- Suitable for wash-down

- Explosion-proof CSA certified Class II, Division I and Class I, Division II available

Zero to 100% Feed Rate Adjustability

Each electromagnetic feeder is controlled by a JVI thyristor controller enabling:

- Zero to 100% linear feed rate adjustability

- Instant start / stop

- Local manual operation available

- PLC interface for remote operation in loss-in-weight (L-I-W) or gain-in-weight (G-I-W) scaling applications

- Custom control packages are available for exact process requirements