Electromechanical vibrating conveyors are time-tested bulk material handlers.

Gentle transport of material over long distances

Electromechanical vibrating conveyors transport materials up to 60 feet in light, medium, and heavy-duty applications.

They provide gentle handling of material with virtually no degradation. The vibration is applied as a “micro-throw” motion to convey material reliably and consistently.

Vibrating conveyors gently transport materials for distances up to 60 feet.

Industrial grade.

For over 30 years, JVI has provided electromechanical vibrating conveyors to industrial customers across North America and around the world. JVI vibrating conveyors are used in a wide array of industries, including aggregates & mining, steel, recycling, chemicals, food & beverage, and more.

JVI conveyors can be configured to handle almost any type of material you need to move. Each JVI electromechanical conveyor is designed specifically for the application, material size, density, bulk material characteristics, and work envelope constraints.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Custom vibrating conveyors engineered for your specific application.

Every bulk material handling process poses its own unique challenges. The type and amount of material being conveyed and environmental conditions vary by industry and company.

The JVI engineering team works closely with our customers to deliver electromechanical vibrating conveyors custom-designed and built to handle their exact material and environmental requirements.

New Conveyors Retrofit to Your Existing Process

The JVI engineering team excels at designing new conveyors to retrofit into your existing process. This means you get all the benefits of a new higher performing conveyor without the time and cost of a process redesign.

Minimum Headroom

Conveyors can be designed for installation into tight work envelopes. Low profile design options are available in single mass or natural frequency conveyors when vertical space is limited.

Gentle Conveying

JVI vibrating conveyors move products gently, making it an ideal solution for friable or fragile material.

Dust Management

An integrated cover with inlet and outlet featuring dust-tight collars is optional in applications where dust management is a priority.

Explosion Proof to Food Grade

JVI conveyors can be constructed with stainless steel food grade requirements and with explosion-proof motors for hazardous areas and explosive materials.

Motors rated to work hard in your application.

JVI conveyors are powered by electromechanical unbalanced motors designed to work in our vibrating equipment. Motors are selected per each application’s requirements. Motors are:

- Available in over 94 different models available including 3600, 1800, 1200 and 900 RPM versions

- Rated for continuous duty at 100% force output and suitable for wash-down

- Explosion-proof CSA certified Class II, Division I

- Groups E,F,G for dust environments

Wide range of liner conveying options.

Various types of abrasion-resistant or corrosion-resistant liners are options for longer wear life and better material flowability:

- Heat treated 450 AR steel

- Chrome carbide, UHMW

- Rubber or stainless steel liners

Options are selected to deliver long life while meeting the application requirements.

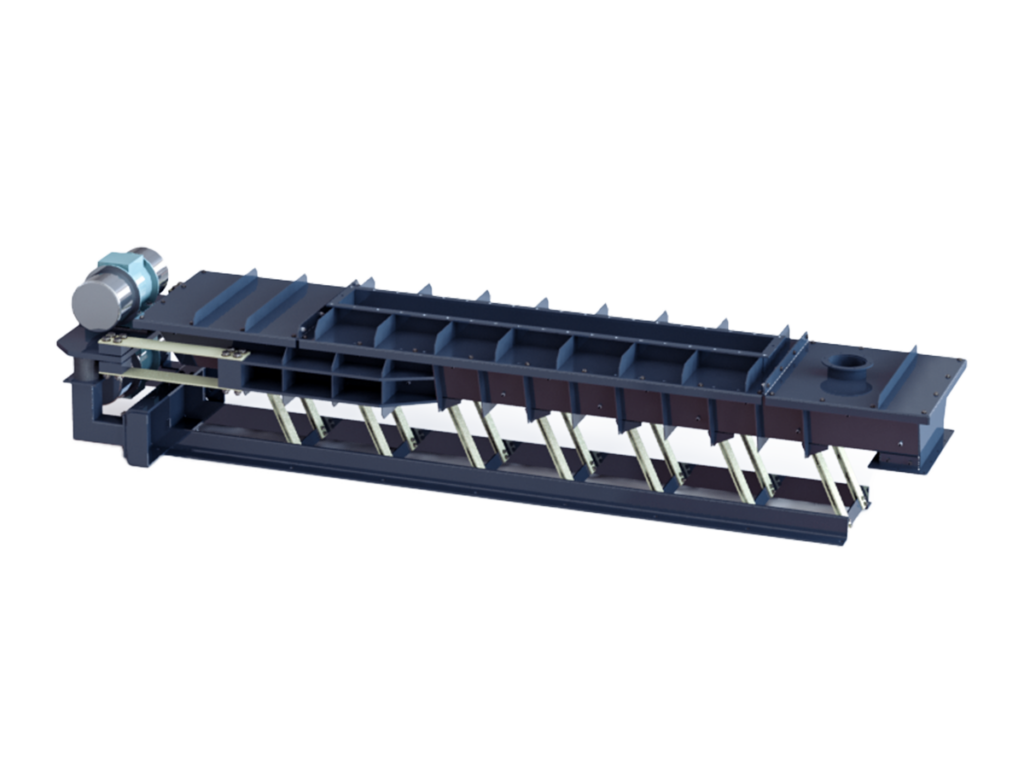

Two conveyor technology options.

Single Mass Vibratory Conveyor

Single mass design provides reliable performance for continuous conveying.

JVI single mass conveyor drives are mounted directly to the conveyor body to form a single mass. This simple design requires fewer moving parts lowering maintenance costs and extending service life.

Single mass vibratory conveyors are used in a broad range of applications capable of handling light-duty processes to heavy-duty. A single conveyor can transport material to distances of up to 30 ft. For longer distances, multiple conveyors can be arranged in a cascading configuration.

Natural Frequency Vibratory Conveyor

Natural frequency conveyors feature low profile and extended conveying.

Natural frequency conveyors are typically used for light and medium-duty applications.

They service long conveying lengths up to 60 ft. and feature a low profile.