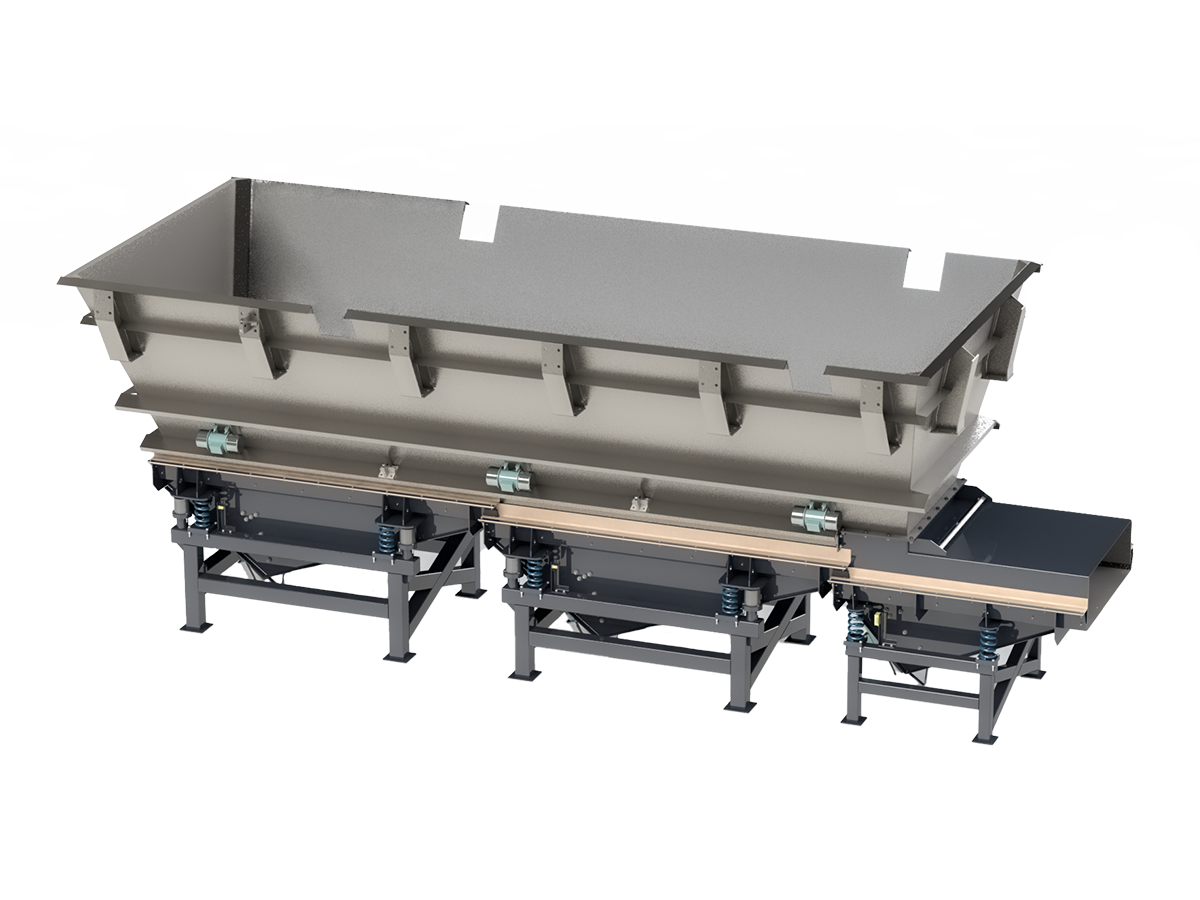

The titan feeder system optimizes discharging of wedge and truck dump hoppers with long slotted openings.

The multi-feeder Titan system discharges large-slotted hoppers at a controlled feed rate.

The JVI Titan Feeder System is a unique multi-feeder system for discharging large-slotted hoppers in railcar and truck unloading facilities. These heavy-duty, cascading electromechanical feeders are mounted below large hoppers and deliver a controlled feed rate onto take away systems or downstream processes.

Titan railcar and truck unloading feeders are energized by a programmable logic controller (PLC) for exact control. They are programmed with JVI’s proprietary algorithm for optimal hopper unloading and processing.

The JVI Titan Feeder System is a unique multi-feeder system for discharging large-slotted hoppers in railcar and truck unloading facilities.

Avoid bulk material compaction. Improve unloading.

Unlike belt or apron feeders, the Titan feeder system discharges material from the discharge end backwards so only free-flowing material is being moved. This creates a clear path for material to feed, avoiding compaction of static material in the direction of flow. The Titan series of cascading feeders handles dissimilar materials seamlessly. These unique characteristics can allow for reduced pit depth requirements, stack up heights, and excavation costs.

Heavy-duty industrial feeders.

The JVI Titan railcar and truck unloading feeder was introduced in 1999 and has been adopted across many industries, including aggregates & mining, coal, steel, recycling, terminals, and more.

The Titan feeder is electromechanically driven by unbalanced vibratory motors – or optional exciter drive gearboxes – that can be configured to handle a wide range of materials.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Discharge front to back.

How it works:

The long-slotted hopper above the Titan feeder is loaded by truck or railcar. The material load is detected, and the Titan System is energized.

Once energized the proprietary algorithm in the PLC sequences the feeders to unload the hopper from the discharge backwards from the master feeder back.

Titan railcar and truck unloading feeders are run by variable frequency drives (VFDs) to allow feed rate adjustability to hit the exact desired unloading rates and to accommodate different materials.

Cascading feeders discharge from the Master Feeder first, followed by Feeder 2 and then Feeder 3, optimizing the flow out of storage.

The JVI Material Testing Lab provides testing of the bulk material properties in a simulated application.

With this data, JVI engineers confirm the feeding and conveying characteristics of the bulk material and optimize design.

Simple design means less wear-and-tear and reduced impact damage.

Compared to belt and apron feeders, the Titan Feeder System features a low average system duty and distributed utilization of the cascading vibratory feeders reduce maintenance costs and downtime. A residual layer of material remains on the feeder platform to protect against impact damage when charging the hopper.

Customized to your application.

JVI customizes each Titan Feeder System to meet the exact application, discharge rates, hopper volumes, and work envelope requirements for each customer.

Titan feeders are electronically adjustable with pre-set capabilities that can handle many types of bulk material from the same hopper.

Low Energy Consumption

The sequencing of the multi feeder system optimizes the flow of material out of storage reducing the effects of the material head load. This allows for a lower energy consumption when compared to belt and apron feeders that are burdened by the full effects of the material head load.

Minimal Vertical Head Room

The Titan Feeder System reduces the vertical height required for the unloading pit. The reduction in height allows for lower pit excavation and construction costs while reducing water table concerns.

High Storage Capacities

By incorporating long slotted hoppers and the Titan Feeder System, a plant can store maximum material volume in a smaller work envelope reducing the pit depth and installation costs.