Vibratory scalping screens remove oversized bulk material to protect processing equipment.

Risk of damage is reduced and downstream equipment operates more efficiently.

Scalping screens – also called safety screens – provide coarse separation of oversized bulk material, so that only on-spec material enters the next phase of the production process.

JVI vibratory scalping screens are used in production processing to ensure consistent flow of on-spec bulk material. Downstream equipment operates more efficiently and the risk of equipment damage caused by oversized or contaminated material is reduced.

Each JVI scalping (safety) screen is custom designed and manufactured to meet the requirements of the intended application.

Vibratory scalping screens separate oversized bulk material to protect processing equipment and improve process efficiency.

Industrial-grade scalping screens.

JVI has delivered industrial-grade vibratory scalping screens to industries across North America and around the world since 1991.

JVI vibratory screens are used widely across many industries, including recycling, mining & aggregates, steel, plastics, pharmaceuticals, and food & beverage.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Coarse separation of oversized bulk material for optimal production.

JVI vibratory scalping screens are used for coarse separation of oversized materials. Each screen is designed to maximize the probability that oversized particles do not pass through the screen deck. Coarse separation also assure that all of the on-spec material continues to move downstream in the process.

Protect Downstream Equipment

By removing oversized material from the process, scalping screens help assure longer operating lives of downstream equipment. This means downstream equipment such as crushers receive on-spec material to ensure they run at their optimal output.

Optimal Screening Efficiency

Each vibratory scalping screen is designed to maximize the probability that all on-spec particle size pass through the screen deck, while large oversized materials pass over the screen.

Each screen is designed and manufactured to meet the requirements of the work envelope, the process, and the types of bulk material to be screened.

The JVI Material Testing Lab allows for testing of the bulk material properties in a customer’s application.

With this data, JVI engineers evaluate the screen-ability of the bulk material and optimize for screening efficiency.

Custom engineered screens built for your application.

Every application comes with its own unique challenges. The type and amount of material to be screened, the desired cut sizes, the environmental conditions of the operating location are all variables that govern material screening efficiency.

The JVI engineering team works closely with customers to provide a completely custom scalping screen solution designed to handle the exact material and environmental requirements.

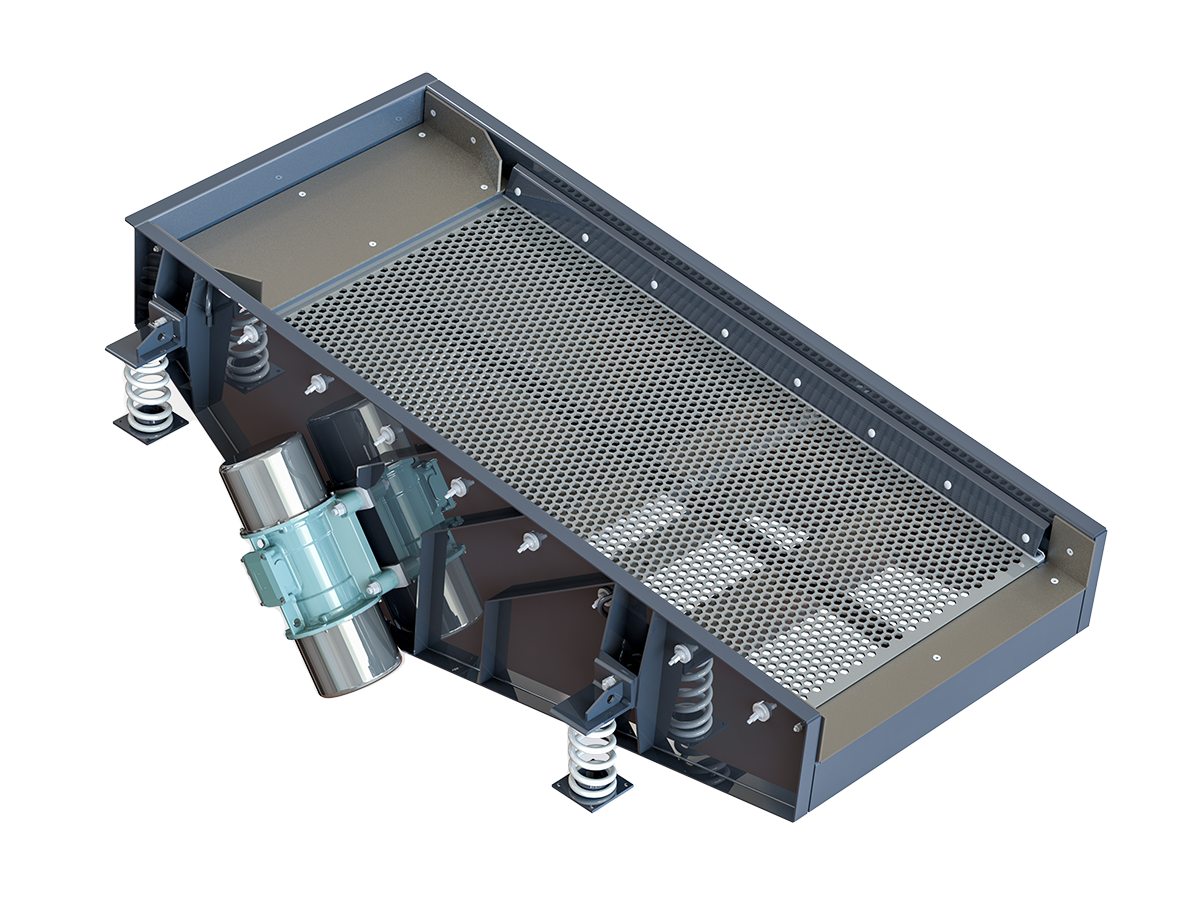

Application Specific Decks

Other screen deck options include:

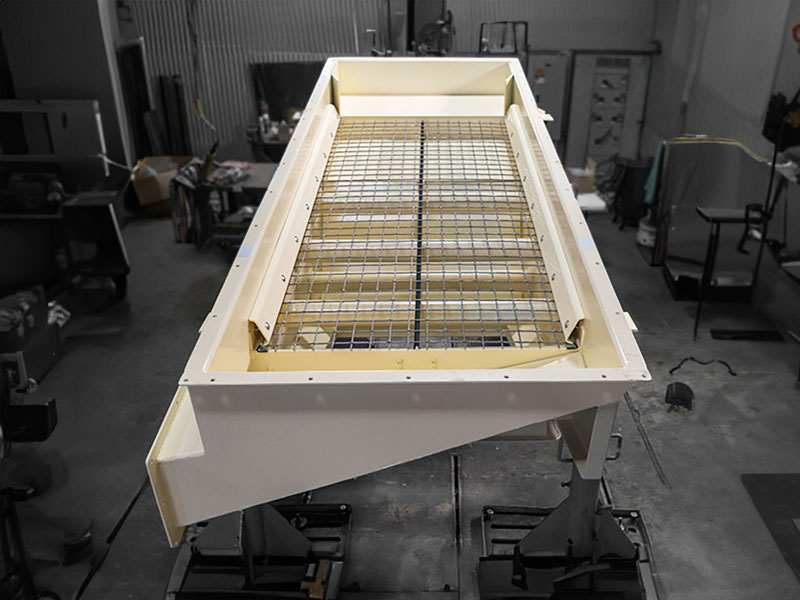

- Woven wire decks used in many applications featuring larger open areas.

- Wedge wire decks are typically used for dewatering applications.

- Perforated decks are used for abrasive materials for longer wear life.

- Rubber Decks are used for highly abrasive and / or high temperature material.

- Polyurethane Decks are used to provide 4-5 times wear life with abrasive material.

- Grizzly Fingers are used to provide coarse screening.

Light, Medium, and Heavy-Duty Applications

JVI offers a wide range of drive options to handle light-duty applications, such as food & beverage, pharmaceuticals or plastics, to heavy-duty applications, such as mining & aggregates or recycling.

Dosing drives, electromechanical unbalanced motors, exciter drives, and to electromagnetic drives are available options to fit each customer’s application.

Application Specific Designs

JVI offers deck designs to meet customer-specific process requirements with one, two, or three decks.

This allows material to be separated into two, three, or four distinct material flow streams based on particle size.

JVI offers a wide variety customization options including side discharge, covers, inspection ports, and materials of construction.

Explosion Proof and Hazardous Location Certified

JVI scalping screens are available with explosion-proof motors with CSA & ATEX certifications where dust ignition is a concern. All JVI vibratory scalping screens are available with Class II, Division I certifications and ATEX equivalent.

Food Grade and Washdown Ready

JVI scalping screens are suitable for food grade and pharmaceutical applications with stainless steel construction finished to the exact mechanical or electro-polish requirements.

Built to Operate in Tough Environments

For tough environments, JVI scalping screens are designed with more robust, thicker material of construction, and abrasion resistance liners on wear areas.