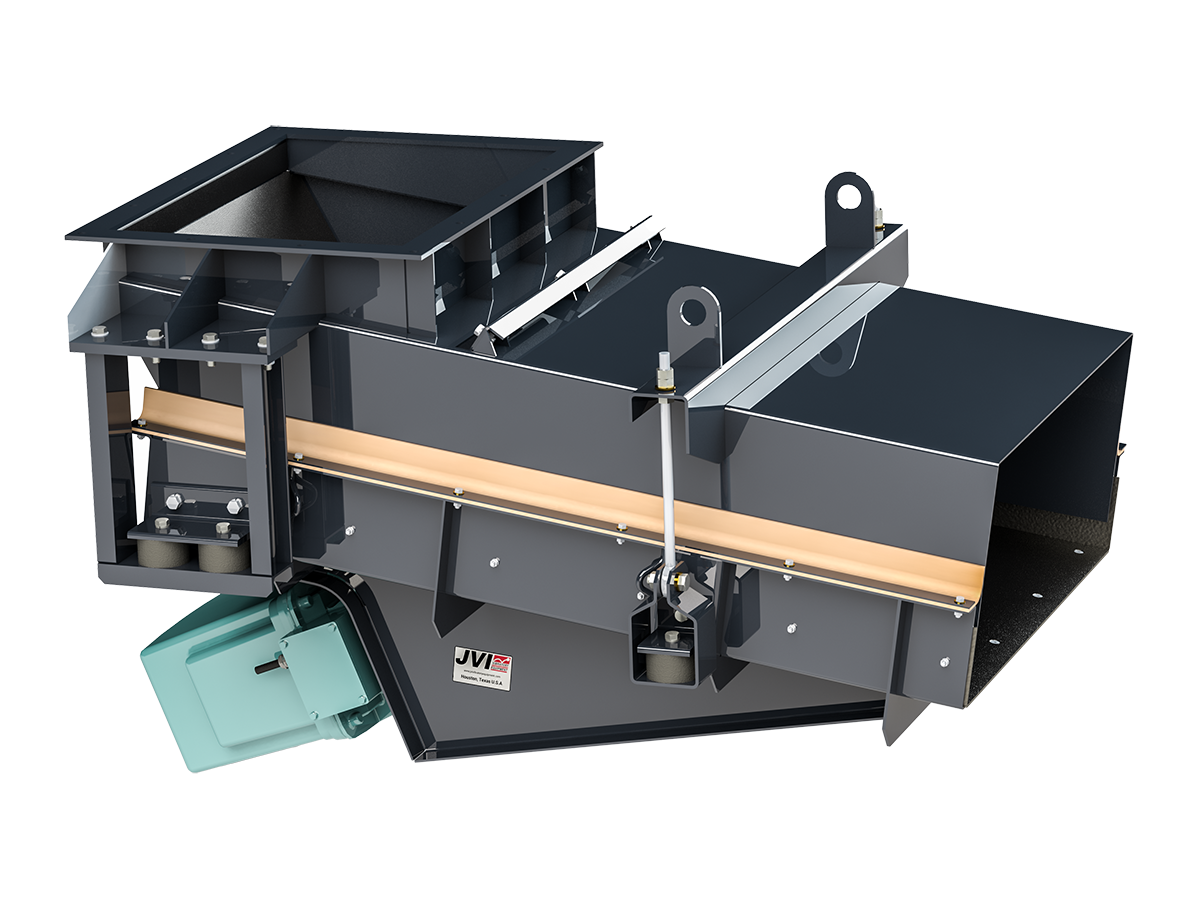

Built to last, magnetically-driven pan feeders ensure precise bulk material feed rates.

Custom designed for your light, medium, or heavy-duty applications.

JVI electromagnetic pan feeders move bulk material in light-duty to heavy-duty applications at exact flow rates. The electromagnetic motor delivers 100% feed rate adjustability, instant stop/start capability, and rugged construction for precise, repeatable performance in even the toughest of environmental conditions.

Every JVI electromagnetic pan feeder is designed specifically for the application and work envelope constraints in your process. Electromagnetic motors are one drive option for Vibratory Pan Feeders. View also Electromechanical motors.

The JVI electromagnetic pan feeder moves bulk material in light-duty to heavy-duty applications at exact flow rates.

Proven performers.

JVI electromagnetic pan feeders are proven performers used widely across many industries, including plastics, chemicals, food & beverage, mining and aggregates, steel, recycling and more.

For over 30 years, JVI has deployed electromagnetic pan feeders to customers across North America and around the world.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Engineered for precise bulk material flow.

Tailored to your process.

The JVI engineering team works closely with our customers to deliver electromagnetic pan feeders custom-designed and built to handle their exact material and application requirements in your process.

Precise feed rate control improves industrial processes.

The precise feeding and control characteristics of the electromagnetic pan feeder provides advanced systems integration and process control. Zero to 100% feed rate adjustability makes them ideal solutions for packaging or batching applications where accuracy is critical.

Same process, better performance.

The JVI engineering team are experts at designing new feeders to retrofit into your current process. This means you gain all the benefits of a new, higher-performing feeder technology without the cost or disruption of changing your current process.

Food Grade to Explosion Proof

From stainless steel pans required for food grade applications to explosion-proof drives for hazardous areas, JVI feeders are constructed to meet the specific demands of each unique application.

Electromagnetic pan feeders custom-designed with controls built to integrate with the existing batching process in this steel mill.

Chute work package supports the feeder, ensuring reliable material flow from the vessel into the downstream process.

Stainless steel pan feeders meet specific food-grade requirements.

The JVI Material Testing Lab provides testing of the bulk material properties in a simulated application.

With this data, JVI engineers confirm the feeding and conveying characteristics of the bulk material and optimize design.

Superior feed rate control and reliability.

JVI electromagnetic pan feeders feature both rugged construction and precise feed rate control for reliable performance.

The electromagnetic drive generates a high frequency, low stroke action transmitted to the bulk material that enables control and precision in material feed rates. Each feeder is factory tuned and works in conjunction with a thyristor controller.

The controller adjusts the amplitude or micro-throw of the material being conveyed in a linear manner, delivering precise feed rate adjustability that is best-in-class.

From grams per minute to tons per hour.

The JVI electromagnetic pan feeder is capable of feeding only a few grams per minute up to 750 tons/hour.

Zero to 100% linear feed rate adjustability.

Each electromagnetic feeder is controlled by a JVI thyristor controller that delivers:

- Zero to 100% linear feed rate adjustability

- Instant start / stop capability

- Local manual operation availability

- PLC interface for remote operation in loss-in-weight (L-I-W) or gain-in-weight (G-I-W) applications

- Custom control packages available for exact process requirements

No lubrication required.

JVI electromagnetic feeders feature quiet operation and minimal maintenance. They are tuned at the factory and do not require field tuning, greasing or lubrication making them virtually maintenance free.

Electromagnetic drives rated to work in any application.

JVI feeders are powered by electromagnetic drives exclusively for our vibratory equipment and selected per application requirements:

- Wide range of models including 25 Hz, 30 Hz, 33 Hz, 40 Hz, 50 Hz and 60 Hz versions

- Suitable for wash-down

- Explosion-proof CSA certified Class II, Division I and Class I, Division II available