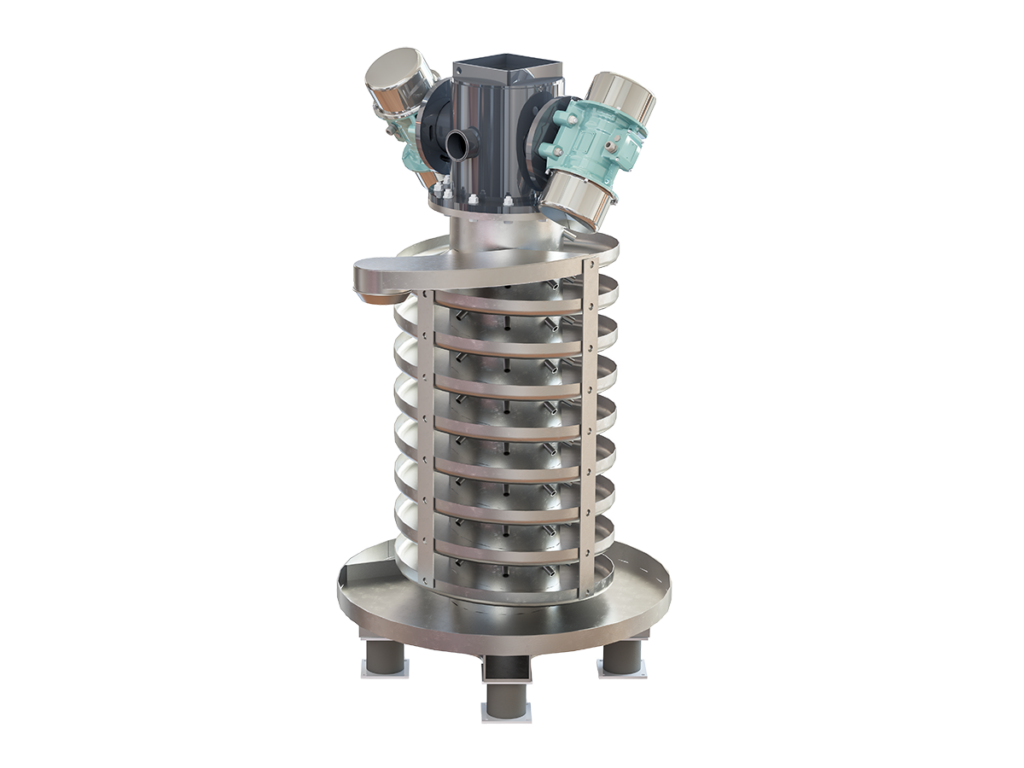

Vibrating spiral elevators convey bulk material vertically in compact areas.

Convey bulk solids, granules, powders or fine materials gently at controlled feed rates.

JVI vibrating spiral elevators are proven solutions for conveying bulk material up to 34 feet vertically, at a rate up to 28 tons/hour. Vibrating spiral elevators feature gentle handling of the product enabled by applied vibratory technology. Products are moved upwards or downwards by our “micro-throw” motion.

For over 30 years, JVI has provided spiral elevators to customers across North America and around the world.

At work in a wide variety of industries.

These spiral elevators convey material consistently, especially in compact areas, across a wide variety of industries and materials, including plastic pellets, recycled products, glass frit, explosive powders, pharmaceuticals, food & beverage, and more.

Every JVI vibrating spiral elevator is designed specifically for your application and work envelope constraints. Operating parameters, such as frequency and stroke are set individually for each elevator. Spiral elevators can be configured to thermally treat bulk material while conveying.

Vibrating spiral elevators are proven solutions for conveying bulk material vertically, at a rate up to 550 cu ft/hour.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Minimal part design keeps it simple for superior conveying performance and reliability.

Minimal Part Design = Higher Run Time

JVI has developed a simple design for our vibrating spiral elevators that uses fewer moving parts.

Simple design combined with high quality manufacturing, JVI spiral elevators keep working at higher run times, in the harshest industrial environments, and provide a long and reliable service life.

Variable Frequency Drive for Process Flexibility

JVI spiral elevators typically operate with an optional variable frequency drive (VFD). This allows the operator to optimize retention time of the material being conveyed to control feed rate or thermal treatment.

Spiral Elevator in Action

This video shows a spiral elevator conveying shredded bulk material vertically to a container. The shredded material is moved gently upward by “micro-throw” motion.

JVI spiral elevator performing forced air cooling in a plastics plant.

Top or Bottom Motor Mounting

Customized for the available space and process requirements, motors are mounted at either the top or bottom of the elevator.

- Top-mounted motors allow for lower inlet height dictated by the equipment feeding the elevator.

- Bottom-mounted motors allow for easier maintenance and adjustments to the motors.

Thermal Treatment While Conveying

Bulk material can be cooled or dried in the conveying process to improve the end product quality. JVI spiral elevators can be designed to thermally treat materials using either air vents for direct cooling/drying, or jacketed flights for contact cooling via water.

Static Covers for Dust Control

Dusty material can be contained inside the elevator with an integrated static cover.

Custom designed static covers can be fitted with visual inspection ports which allow operators to view the product conveying during operation. Vent ports can also be incorporated into the design to allow for customer supplied dust collection systems.

Custom engineered to work in your light, medium, or heavy-duty application.

Every bulk material handling process comes with its own unique challenges. Type and amount of material being conveyed and the environmental conditions of the operating location vary by industry and company.

The JVI engineering team works closely with customers to deliver spiral elevators custom-designed and built to handle the exact material and environmental requirements.

Easy Integration

The JVI engineering team excels at designing spiral elevator solutions to fit your current process. This means you get all the benefits of a new spiral solution without the cost and time to redesign your current process.

Going Up or Coming Down

Spiral Elevators can be designed to convey vertically up or down, depending on the needs of the application.

Small Workspace Footprint

With minimal workspace requirements, Spiral Elevators are easily incorporated into the constraint of tight spaces.

Gently Vibration Maintains Material Integrity

Ideal for conveying friable or fragile materials, spiral elevators ensure that materials do not degrade through the gentle vibratory motion used to convey.

Food Grade to Explosion Proof

We deliver spiral elevator solutions in a wide variety of settings. From stainless steel for food grade processing to explosion-proof motors for hazardous areas, we build spiral elevators to meet each unique application.

18-foot vibrating spiral elevator to be installed in a steel plant.